Polysilicon Ditrctional Solidificateion Rauv

Daim ntawv thov

Cov cuab yeej no koom nrog hauv hnub ci ingot ntau lawm thiab ua kom zoo dua ntawm cov khoom siv semiconductor.Nws yog dav siv rau kev tsim cov nyiaj-raws li, cobalt-raws li kub kub alloys, thiab cov khoom zoo uas ua los ntawm cov alloys feem ntau siv rau hauv aerospace turbine cav kev lag luam, tsheb, biomedical teb, chemistry teb thiab lom zem teb.

Nta

Kev tswj xyuas siab, kev hloov pauv dawb ntawm cystallization ceev, graphite tsis kam lossis induction cua sov melting txoj kev, nce yaj stirring, ceev melting ceev.Tshwj xeeb cua sov fais fab mov yog saws rau directional solidification tshav kub preservation, uas muaj peb-theem tam sim no sib npaug thiab tsis tshua muaj nqi txij nkawm.148 cua sov txheej txheem nkhaus tuaj yeem teeb tsa nrog qhov ntsuas kub tsis tu ncua.Lub tshuab nqus tsev ua kom sov lub cev yog siv rau hauv lub cub tawg chamber, uas muaj lub tshuab nqus tsev siab thiab siv ceev ceev.

Technical Parameters

| Melting Capacity | 10-450 KG |

| Hwj chim | 40-450 KW |

| Tsim kub | 1700 ℃ |

| Ua haujlwm kub | 1450 ℃ |

| Kub nce tus nqi | 40 ℃ / min |

| Rauv kub uniformity | +5 ℃ |

| Lub tshuab nqus tsev txwv | 6.67 * 10-2Pa |

| Siab nce tus nqi | 0.01PaL/S |

| Rated inflation siab | 0.05 Mpa |

| Txoj kev Casting ingot | directional solidification nrog crucible ntog / tuav rauv lifting |

| Servo tswj ntau yam | 0.01mm-0.5mm / min |

| Crucible ceev rov qab ceev | 80-100mm / Min |

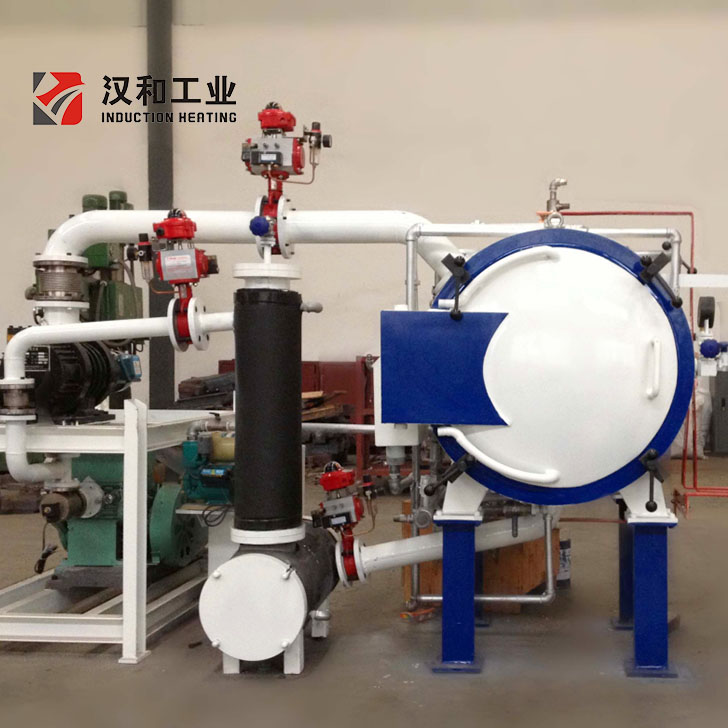

Daim duab nthuav dav