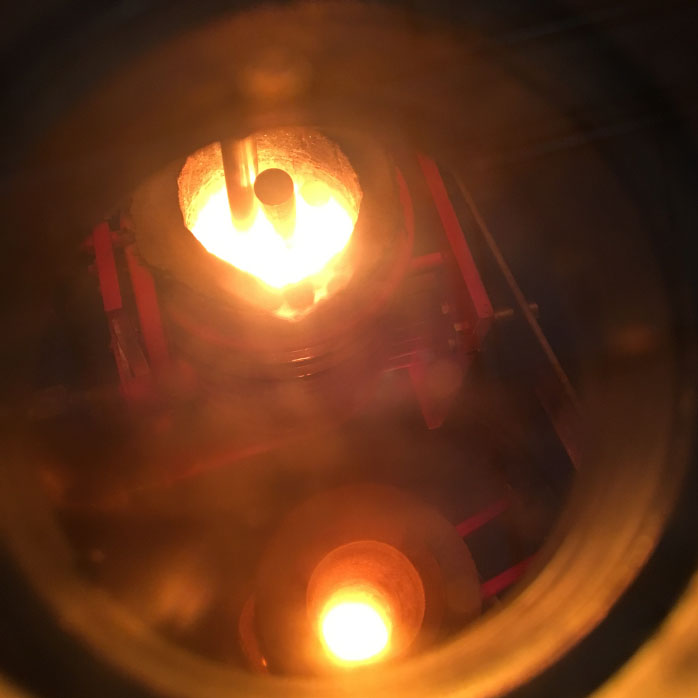

Customized Vacuum Induction Melting Rauv

Kev piav qhia

Cov khoom raug them rau hauv qhov cub induction nyob rau hauv lub tshuab nqus tsev thiab lub zog yog siv los yaj cov nqi.Cov nqi ntxiv yog ua kom coj cov kua hlau ntim rau qhov xav tau yaj lub peev xwm.Cov hlau molten yog refined nyob rau hauv lub tshuab nqus tsev thiab cov chemistry kho kom txog rau thaum lub meej yaj chemistry tiav.Cov impurities raug tshem tawm los ntawm cov tshuaj tiv thaiv, disassociation, flotation thiab volatilization.Thaum qhov xav tau yaj chemistry tiav, lub preheated tundish yog ntxig los ntawm lub valve cais kub tundish insertion xauv.Qhov no refractory tundish yog positioned nyob rau hauv pem hauv ntej ntawm lub induction rauv thiab molten hlau yog poured los ntawm tundish, mus rau hauv lub tos pwm.

VIM yog cov txheej txheem siv los ua superalloys, stainless hlau, hlau nplaum thiab roj teeb alloys, hluav taws xob alloys, thiab lwm yam uas xav tau cov alloys siab.

Kev Sau & Daim Ntawv Thov

Nws yog tsim los ntawm lub cub tawg lub cev, npog, sensor, melting crucible, thermal rwb thaiv tsev khoom, them lub thawv, npog elevating mechanism, nqus tsev, nruab nrab zaus hwj chim, hluav taws xob tswj txee, ntsuas kub ntsuas.Nws yog tsim rau smelting thiab precision casting rau ferrica-raws li, npib tsib xee-raws li, high-temperature alloy thiab lwm yam leej alloy thiab magnetic khoom.

Technical Parameters

| Qauv | Peev xwm (KG) | Ltd Vac.(Pa) | Qhov siab tshaj plaws (℃) | Lub zog (KW) | Zaus (Hz) |

| ZLP-5 | 5 | 6.67 * 10-3 | 1800 | 50 | 8000 |

| ZPO-10 | 10 | 6.67 * 10-3 | 1800 | 50 | 4000 |

| ZPO-25 | 25 | 6.67 * 10-3 | 1800 | 100 | 2500 |

| ZLP-50 | 50 | 6.67 * 10-3 | 1800 | 100 | 2500 |

| ZPO-100 | 100 | 6.67 * 10-3 | 1800 | 160 | 2500 |

| ZPO-200 | 200 | 6.67 * 10-3 | 1800 | 250 | 2500 |

| ZLP-300 | 300 | 6.67 * 10-3 | 1800 | 300 | 1000 |

| ZLP-500 | 500 | 6.67 * 10-3 | 1800 | 500 | 1000 |

| ZLP-1000 | 1000 | 6.67 * 10-3 | 1800 | 700 | 1000 |

| ZLP-1500 | 1500 | 6.67 * 10-3 | 1800 | 1000 | 1000 |

| ZLP-2000 | 2000 | 6.67 * 10-3 | 1800 | 1500 | 1000 |

Kev pab cuam tom qab muag

Peb muaj cov kws tshaj lij engineers los nruab thiab kho cov khoom siv, thiab muab lub sijhawm lav 1-3 xyoos rau cov khoom siv zoo.Peb cov engineers uas yog lub luag haujlwm rau kev pab cuam tom qab muag yuav them nyiaj mus ntsib kws tshaj lij rau koj txoj haujlwm zoo.

Daim duab nthuav dav